The anchoring and mooring system holds the floating platform in place and provides the mechanical stability that it requires throughout the lifetime of its operation.

Anchors and mooring lines are the key components of the system. The structures can range from simple shore anchoring, typical in smaller water bodies or very deep ones, to highly complex anchors suitable for reservoirs with great variations in water level, as can be the case in some hydropower reservoirs.

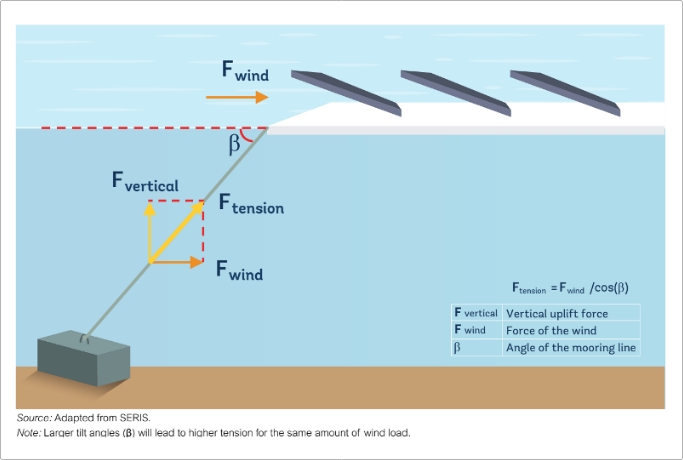

Wind loads and water movements (currents) are particularly important parameters to consider in order to ensure the integrity of the entire floating platform and its anchors. Failure of the anchoring or mooring system could have severe impacts on the project, as rectification might be difficult.

Anchoring systems

We have 2 types of Anchoring System

- Bottom Anchoring – are dead weights such as concrete blocks that rely on their mass and helical anchors that screws drilled into the bed of the water body

- Anchoring on the bank of the shore – to pile the anchors firmly to the ground

Mooring Lines

Usually made of wire rope, galvanized steel wires, and chain. Many possible combinations of line type, size and configuration can be used to achieve the required mooring performance.

Design Considerations

Site Assessment: Detailed analysis of the water body (depth, current, wave action, wind patterns) is essential for designing an effective anchoring and mooring system.

Wind load resistance is normally calculated from the drag forces developed by the float structures. Wind speed and direction data are also the critical to consider as it determines the maximum forces on the island. As the mooring lines are mainly used to constrain the lateral movements, the should be as horizontal as possible to avoid excessive tensile stress under wind load.

Environmental Impact: Minimizing ecological disruption is crucial. The materials and methods chosen should have minimal adverse effects on aquatic life and water quality. Durability and Maintenance: The system must withstand extreme weather conditions and require minimal maintenance. Regular inspections are necessary to ensure long-term performance.

Durability and Maintenance: The system must withstand extreme weather conditions and require minimal maintenance. Regular inspections are necessary to ensure long-term performance.